Reinforced Furcation Tubing

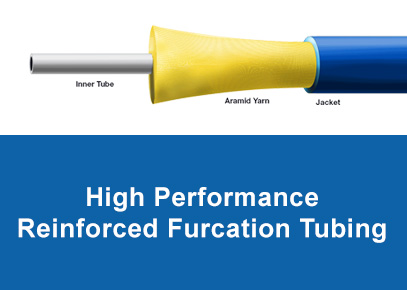

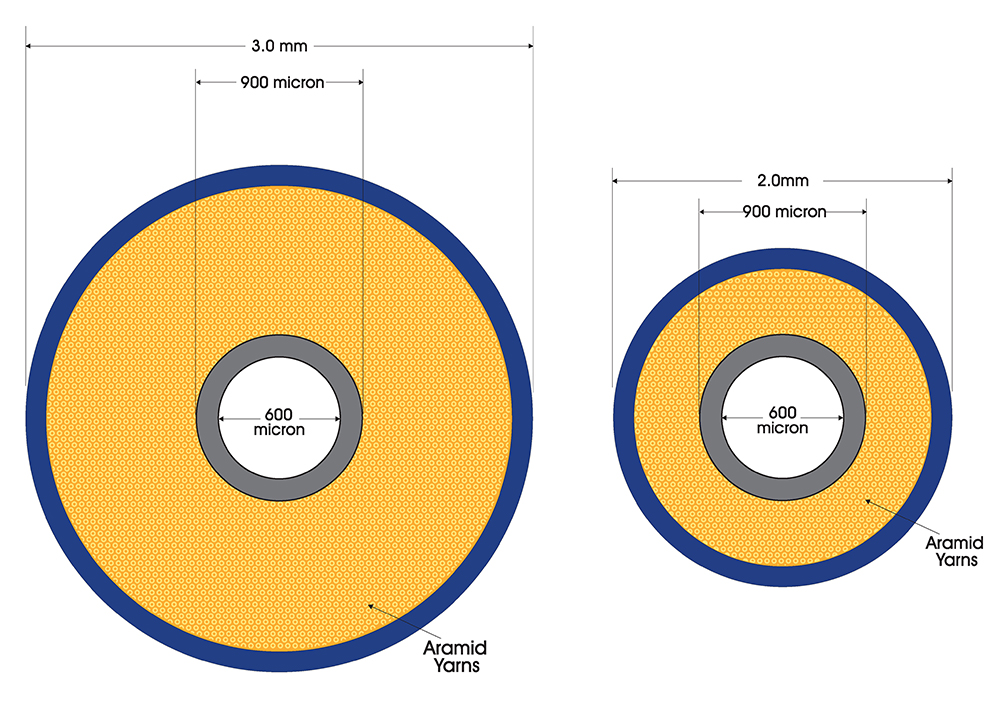

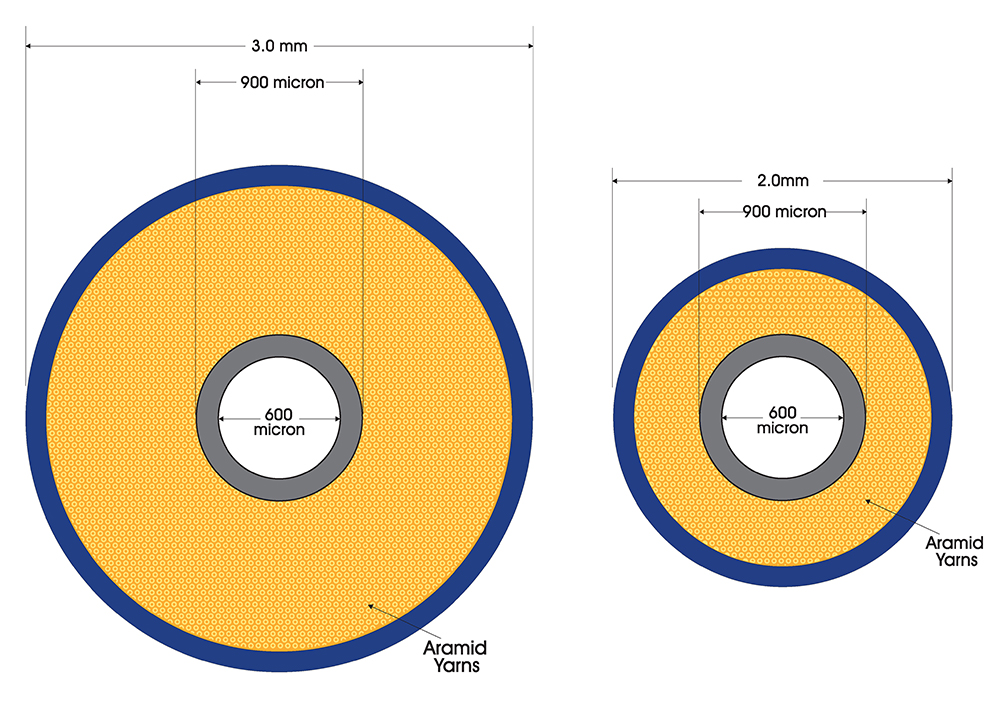

Reinforced furcation tubing is ideal for building up unsupported fiber or breaking out multi-fiber cables for termination. HCA reinforced furcation tubing is designed for low shrinkage over a wide temperature range. The construction consists of an inner tube surrounded by aramid yarn and an outer jacket. The diameters of the finished tube is designed to match commonly available connector styles. The inner tube can be sized to accept coated or buffered fiber. HCA also has a non-ruggedized tube offering where aramid fiber is not necessary for applications such as with fiber cassettes, couplers and splitters. HCA’s furcation tubes are designed and color matched to work with our NanoCore™ line of micro distribution fiber optic distribution cables in the 4 standard colors: yellow, aqua, orange and Erika violet.

Features & Benefits

Features & Benefits

- Tight dimensional control for easy fiber insertion

- Aramid reinforced for added mechanical protection

- UL94 V-0 material options

- Low shrinkage for improved environmental performance

- Tube can be customized to customer designs (minimum order quantities may apply)

- Jacket color matched to the standard HCA fiber optic cable colors: Orange, Yellow, Aqua, Erika Violet

- Standard inner tube color is white

Applications

- Breaking-out/Fanning-out cables to connectors

- Patching active devices

- Specialty fiber protection

- Coupler and splitter applications

A typical ruggedized furcation application will use the Hitachi Cable America, Nanocore™ series of cables. These loose-tube, UL rated cables are popular for their small diameters, flexible cabling and high fiber counts. Furcation tubing for these designs to LC or SC duplex connectors is common. The Nanocore series is described below:

NanoCore™ cables offer 250 micron fiber optic strands in a loose tube cable design. NanoCore™ cables allow for a higher fiber strand count in a very small overall diameter cable. Each fiber strand is color coded for easy identification. The cable is flexible and easy to handle and uses lightweight, flexible aramid yarns to enhance strength. Subunits with 12 strands are only 2mm in diameter. NanoCore™ Interconnect Micro Distribution cable is ideal for MPO (MTP®) style connectors where higher data rates are desired. Supported applications include gigabit, 10, 40, 100 and 400 gigabit Ethernet. NanoCore™ cables are made in USA.